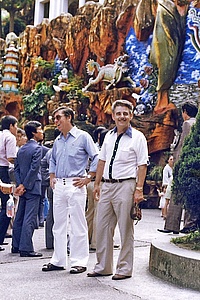

Walter Pepperl, Ludwig Fuchs, Wilfried Gehl

Ludwig Fuchs was born in Freising on July 21, 1920. After the Second World War, he returns to Freising as a first lieutenant to his wife Amalie, née Sponagel, and works as a banker at the Bayerische Hypotheken- und Wechselbank.

Born in Karlsbad on May 5, 1921, Walter Pepperl is a radio technician and is therefore deployed as a telecommunications operator during the war. After the war, he too moves to Freising, where his wife Anny lives, and finds work in the repair department of the Lacher radio store.

Through Anny, the two men get to know each other. In the time of the beginning economic miracle, they soon make the decision to start their own business. The two families move to Mannheim-Sandhofen, and on November 14, 1945, Walter Pepperl and Ludwig Fuchs establish a repair shop for radio equipment there at Sonnenstrasse 32, the apartment of Amalie's parents.

When radio equipment stops working in the postwar era, it is often due to defective power transformers, whose insulating paper layers between the windings often become damp, causing short circuits. New transformers are in short supply, but copper wire is available on the market. Pepperl, a radio technician, therefore decides to make replacement transformers himself and builds a winding machine from used parts. He converted a bicycle speedometer into a winding counter and used the crank drive from an old telephone set.

The business goes so well that a store can soon be opened in Mannheim-Sandhofen "Am Stich", where mainly radios, but also record players, records, vacuum cleaners, waffle irons and light bulbs are sold; even a first tape recorder called Tefifon with so-called sound tapes can be bought. The manufacture of transformers in particular is so successful that the first "real" winding machines can be purchased and production can begin in an adjoining room. Soon Pepperl+Fuchs is supplying Mannheim's industrial companies with its transformers.

After the conversion of the mains voltage from the previous 110 V to 220 V, Pepperl+Fuchs manufactures ballasts for converting the mains voltage for the power supply in the Ludwigshafen area from 1950. This means that older devices can continue to be operated with the new mains voltage. Pepperl+Fuchs builds control transformers for industry. In 1954, the first transformer winder is hired and in 1955, the company moves to Sandhofer Strasse, where a new building can be occupied in 1957.

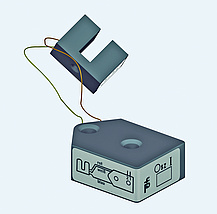

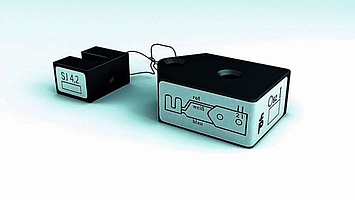

When BASF, an important customer of Pepperl+Fuchs, needed a magnetic amplifier that could also be used in potentially explosive atmospheres, Wilfried Gehl, a graduate engineer, developed the "transductor" for this purpose in 1957. In the meantime, magnetic amplifiers or transducers have long since been superseded by semiconductor technology.

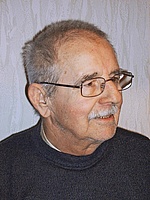

Wilfried Gehl was born on April 14, 1929, the son of a teacher in Hermeskeil in Hunsrück. He grows up with two older brothers and a younger sister in Großlittgen in the Eifel and attends high school in Wittlich. His father is a prisoner of war in England for many years. The mother has to care for the family alone, and the children also have to help out during this time of privation. After graduating from high school, Wilfried Gehl studied electrical engineering at the Technical University of Aachen, majoring in high-frequency engineering. While still a student, he marries his wife Gisela.

In 1956, BBC in Mannheim-Käfertal hires the newly graduated engineer. He moves to Mannheim with his young family and finds a spacious apartment in an apartment building owned by Pepperl+Fuchs in Mannheim-Sandhofen.

This is how he gets to know Ludwig Fuchs and Walter Pepperl, who quickly recognize the special talent of the young graduate engineer. As early as 1957, the extremely fruitful collaboration begins with the development of the transductor for BASF, which will only end with Wilfried Gehl's retirement.

The rapidly advancing automation of technical processes after the Second World War required new types of switches to control the plants. Mechanically operated electrical contacts were not sufficiently safe due to the high currents and associated sparks, especially in potentially explosive areas of the chemical industry.

BASF therefore commissioned Walter Pepperl and Wilfried Gehl to replace these switching contacts with a robust yet small component that works reliably and, above all, safely even in the aggressive atmosphere of the chemical plant with only small switching currents.

The two radio engineers are very familiar with the properties of electric oscillating circuits and find the solution. When a metallic object approaches a suitably constructed resonant circuit, energy is drawn from it because currents are induced in the approaching object, which consume energy. As a result, the current in the oscillating circuit decreases the closer the object approaches. This change can be evaluated in such a way that, at a precisely adjustable distance, a high current can be switched safely via a magnetic amplifier. In this way, the inductive sensor can detect the position of metallic objects in machines without contact and thus without wear.

Based on this principle, Gehl quickly develops the first inductive proximity switch with the designation "Inductive slot sensor SI 2.5", which is connected to the switching device equipped with semiconductor components via only two wires. Today, as a result of the miniaturization of the semiconductor components, the switching device can be integrated directly into the housing of the proximity switch.

Thus the first system for contactless switching in hazardous areas was born. The "inductive proximity switch" is one of the oldest electronic components in automation.

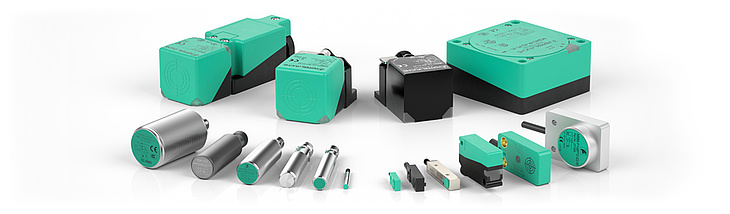

At first, only chemical companies used it. But after a short time, other industries also appreciate that the proximity switch is not only inexpensive, robust and durable, but also reliable and easy to use.

In the following years, the proximity switch develops into the industry standard for contactless switching worldwide. The high demand leads Pepperl+Fuchs to increasingly specialize in electronic sensors for process automation, for packaging and filling plants as well as for the automotive industry, chemical plants or even oil rigs. The principle of the inductive proximity switch has remained unchanged. Since it is always being adapted to new areas of application, whether for packaging machines, weighing or dosing systems, it is still modern 60 years after its invention. Today, the medium-sized family-owned company Pepperl+Fuchs is one of the world's leading companies in the field of industrial sensor technology and the global market leader in intrinsically safe explosion protection.

In 1987, Fuchs and Pepperl hand over the management of the company to the next generation. Ludwig Fuchs dies on May 15, 1997; Walter Pepperl on December 10, 2000. Wilfried Gehl remains associated with the company as a freelancer after the retirement of the two company founders. In addition to his work for Pepperl+Fuchs, he runs his own small company, "Gehl GmbH Elektronische Geräte", at Königsberger Allee 87, directly next to Pepperl+Fuchs.

He enjoys spending his free time with his four children on their weekend property in the Palatinate. In his hobby carpentry workshop, he designs and builds pieces of furniture that are still cherished by the family today. Wilfried Gehl dies on May 12, 2017 in Weinheim. At Pepperl+Fuchs, Wilfried Gehl, who was always in a good mood and friendly, loyal and always helpful, is fondly remembered.