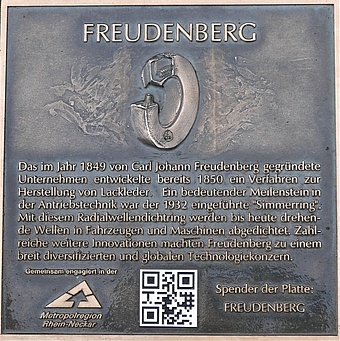

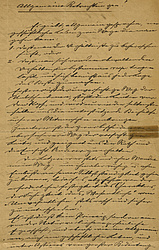

Imitation leather 1844

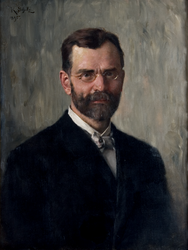

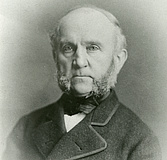

Carl Johann Freudenberg (1819-1898)

Carl Johann Freudenberg was born on May 9, 1819, the son of the innkeeper and mayor Georg Wilhelm Freudenberg and his wife Katharina Elisabeth in Hachenburg (Westerwald). He was only nine years old when his father died and his mother Katharina and her six children moved in with her family living in Neuwied.

After school, 14-year-old Carl Johann is apprenticed to the Mannheim leather shop Heintze & Sammet. Jean Baptiste Sammet, a relative of his mother, takes him on as an employee after his apprenticeship. In 1844, Carl Johann became a silent partner in the company and married Sophie Martenstein.

The economic repercussions of the 1848 revolution led to the insolvency of the leather business. While Sammet continued trading in Mannheim, Carl Johann Freudenberg and Heinrich Heintze acquired the Weinheim tannery from the bankruptcy estate and founded the Heintze tannery & Freudenberg in Weinheim on February 9, 1849.

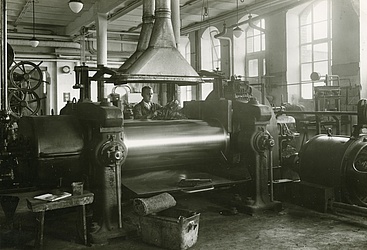

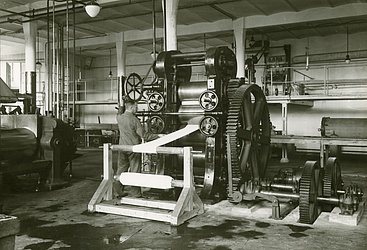

When Eduard Michel, a master tanner trained in France, suggested coating calfskin, the company founders realized the brilliant possibilities offered by the new fashionable patent leather. The first coating factory, financed by Martenstein's father-in-law, is built in Müllheim Valley. The patent leather launched on the market just one year after the company was founded becomes a great success. Leopold Heintze, son of the co-owner Heinrich Heintze, lives in England and takes care of the sales of the new product there. When the patent leather is awarded a medal at the first world exhibition in 1851, sales increase rapidly. By 1855, the company is already one of the largest German tanneries. Patent leather accounts for about 80% of production.

In 1874, co-owner Leopold Heintze died, succeeding his father Heinrich who had already died in 1864. Carl Johann Freudenberg took out a loan and paid out his heirs' share of the capital, making him the sole owner. He renamed the company "Carl Freudenberg". In 1875, he took his sons Friedrich Carl (1848 - 1942) and Hermann Ernst (1856 - 1923) into the company. With Herrmann's help in particular, the company succeeded in transforming the previously handcrafted production of patent leather into industrial mass production while maintaining the same high quality. When the sons became partners in 1887, Carl Johann gave them his most important principles for a successful company: modesty, honesty, a solid financial basis and, last but not least, the ability to adapt to change.

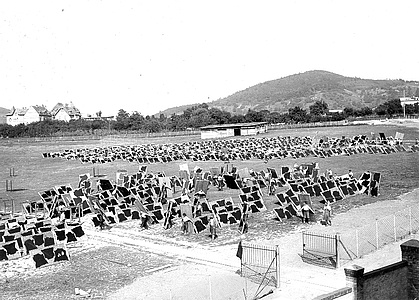

In 1896, a hair laundry was built in the "Zwischen den Dämmen" area between the two branches of the Weschnitz, where the hair from the dehairing of the hides was cleaned and processed for the production of felt, for example for hats.

Carl Johann Freudenberg died on August 6, 1898 and his two sons became sole owners of the company "Carl Freudenberg GmbH".

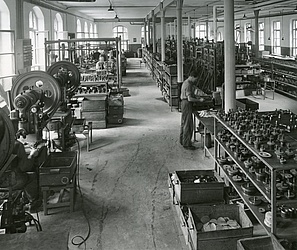

Around 1900, Freudenberg was the first European company to introduce chrome tanning. Hermann Ernst Freudenberg had learned about this process in the USA and developed it further. Instead of tanning liquor made from natural vegetable substances, tanning was now carried out with chrome salts. The new process reduces the tanning time from the previous 18 months to just 18 days. The new chrome leather is also of better quality. It is water-resistant, easy to care for and has a more even surface. In 1912, Freudenberg was one of Europe's largest tanneries with 1,300 employees and sales of 12.5 million Marks.

The First World War brings major problems for the company. Exporting abroad becomes just as difficult as importing raw materials. In addition, many employees were called up for military service. Their work in the tannery was taken over by women. After the end of the war, inflation initially made it difficult to buy raw materials. But after this problem is solved in 1921 by founding a financing company in Switzerland, things slowly start to look up again.

In the meantime, the grandchildren of the company founder, Richard (1892 - 1975), Hans (1888 - 1966), Otto (1890 - 1940) and Walter (1879 - 1957) also bear responsibility in the company. A partnership agreement introduces a corporate constitution. To safeguard the company, it is laid down how management and financial interests are to be regulated in future within the now large family, and operational business is separated from family matters. This enabled the company to continue to develop successfully even after the death of Hermann Ernst Freudenberg in 1923.

The first test for the new directors came at the end of 1929 with the world economic crisis. National protectionism with high tariff barriers became increasingly widespread in Europe and the USA. Foreign trade and with it industrial production fell sharply, the flow of capital to Germany dried up, shoe factories closed and export markets collapsed. Price erosion and mass unemployment meant ruin for many companies at this time, and Freudenberg, Europe's largest leather producer at the time, also went through a difficult period. To avert mass redundancies, Freudenberg introduced the 20-hour week and thus short-time working for everyone.

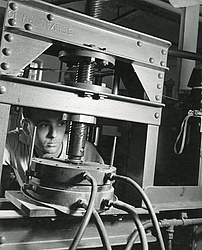

Necessity is the mother of invention: Hans Freudenberg commissioned his plant engineer Walther Simmer (1888 - 1986), who came from Kufstein and had been responsible for the tannery machines since 1919, to develop sleeve seals made of leather waste for the machines.

The felt shaft seals still used on the machines at that time were unable to retain lubricants and gases completely and for long periods, which reduced performance and led to increased wear. On the leather-splitting machines, it was found that ball bearings were destroyed over time by penetrating alkalis because of leaking felt rings.

The point at which a shaft passes from a closed system to an open system must be sealed to prevent liquids or even gases from escaping, for example from a motor housing, on the one hand, and dust, dirt or moisture from entering the housing on the other. This is particularly difficult when the force generated in the motor is to be transmitted out of the housing by the movement of a shaft, a piston or a linkage.

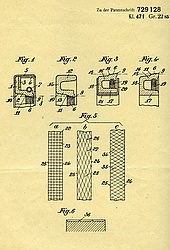

Initially, Simmer already achieved a significant improvement with the leather cuff he devised. After extensive trials, he perfected the seal even further: he installed the leather collar firmly in a sheet metal housing. He improved the sealing performance even further by using a worm spring that pressed against the rotating shaft of the machine, thus increasing the radial contact pressure. As a result, the sealing lip now permanently surrounds the rotating shaft. Freudenberg can now offer the automotive industry a complete installation system as a durable seal instead of the felt seals previously used. Now there is no longer any need to place a collecting container under the engines, because they no longer leak oil. Series production began as early as 1932.

The revolutionary radial shaft seal known as the "Simmerring" becomes a worldwide success. However, it turns out that over time the leather, which is initially impregnated with wax and later with a rubber-like compound, dries out and shrinks. As a result, the seal is only suitable for small shaft diameters. In addition, the first "Simmerrings" were also not temperature-resistant. When it became increasingly difficult to import leather from 1934 onwards as a result of the National Socialists' autarky policy, Freudenberg not only looked for ways to recycle the valuable leather waste but also for materials that could replace leather. In 1927, the first synthetic rubber called BUNA was developed at I.G. Farben in Leverkusen, a consortium of eight German chemical companies. Experiments with it show that BUNA is much more temperature-resistant than leather and is very suitable as a substitute. In 1936, chrome leather is replaced by BUNA.

Two years later, Perbunan was developed from this, which is resistant not only to high temperatures but also to oil, aging, and weathering. With Perbunan, production costs can be significantly reduced, because the seal body is already shaped to fit precisely in the vulcanizing press and the sealing lip is later adapted to the respective application, providing optimum sealing, especially for rotating shafts. In 1936, the first "Simmerring" with Perbunan is launched on the market. Walther Simmer files the patent in 1938, which is granted to him in 1942. Until then, the "Simmerrings" bear the additional stamping "D.R.P. Ang." (German Reich patent pending)

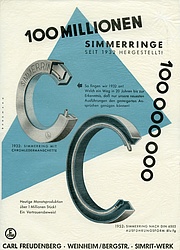

The "Simmering" made Freudenberg the leading specialist in sealing technology. In January 1953, Hans Freudenberg was presented with the 100 millionth "Simmerring". Thanks to countless further developments, "Simmerrings" still reliably seal a wide variety of machines today, from cars to fans or washing machines. In the meantime, seals have been developed with additional functions, for example to measure engine speed or reduce CO2 emissions.

When researchers in the nonwovens test laboratory observed cleaning ladies mopping floors with waste from the nonwoven, the Vileda cloth ("like leather") was born and products for the household were manufactured from 1948.

However, Freudenberg produces its nonwovens not only for Vileda or textile interlinings, but also for sound insulation, cable sheathing, seals, automotive parts and even medical products such as wound dressings enriched with antibiotics or enzymes. Filtration is now a business unit in its own right. Freudenberg is the market leader for automotive cabin air filters.

Perbunan, which was developed for the "Simmerring", is also ideal for shoe soles, drive belts or floor coverings and opens up opportunities for Freudenberg to develop further business areas and expand its product range.

170 years after it was founded, this traditional family business is one of the most successful German industrial companies in more than 30 different market segments, with almost 500 independent companies at 170 production sites in 57 countries. However, leather no longer plays a role since the closure of the last tannery in 2002.

Freudenberg has remained an innovative company and is still owned by some 300 descendants of the company founder. Once a year, they are invited to Weinheim for the Annual General Meeting.