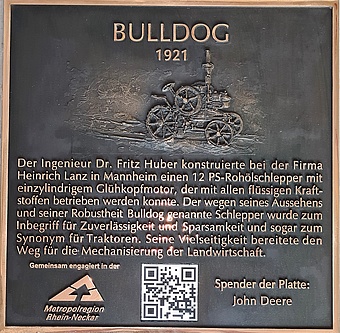

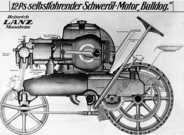

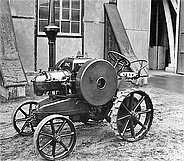

Bulldog 1921

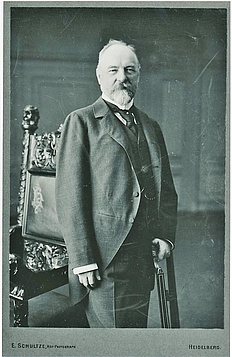

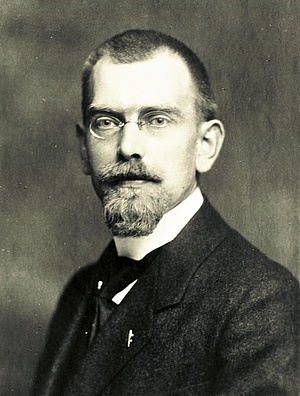

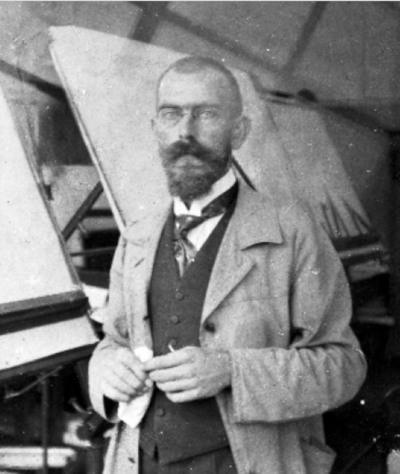

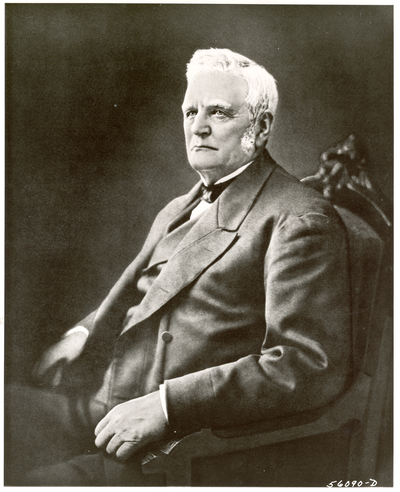

Dr. Fritz Huber (1881 - 1942) Heinrich Lanz Company

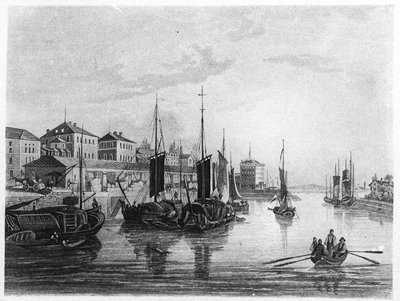

In the middle of the 19th century, Mannheim was the most important economic center in the Grand Duchy of Baden. The Neckar River, navigable as far as Heilbronn, and above all the new Rhine port , opened in 1840 , make Mannheim the most important transhipment center in southern Germany.

The forwarding merchant Johann Peter Lanz from Friedrichshafen on Lake Constance recognizes this favorable traffic situation. In 1842, he founded a branch office in Mannheim for his company, which had expanded from his father's grain business into an agricultural machinery business. At this time, most farmers still cultivate their fields with the help of their plow horses. Only a few could afford agricultural machinery. Often a farmer only produces enough to feed his own family.

The Lanz son Heinrich takes over the management of the branch at the age of 21. Just one year later, he and two locksmiths trained in England set up a repair shop for the agricultural machinery he sold in a garden shed on Schwetzinger Strasse.

This is so successful that it soon has to be enlarged and equipped with steam power. Heinrich Lanz also introduces modern marketing: favorable prices through bulk purchasing as well as stocking a wide range of different machines and spare parts, which he soon also manufactures himself. To this end, the business is extended from Schwetzinger Strasse to the main train station. The machines he offers are exhibited, demonstrated and advice is given to farmers. Heinrich Lanz also does not forget to cleverly advertise the labor-saving machines.

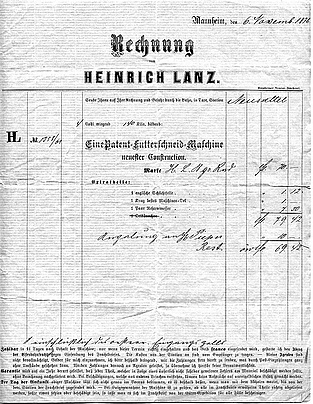

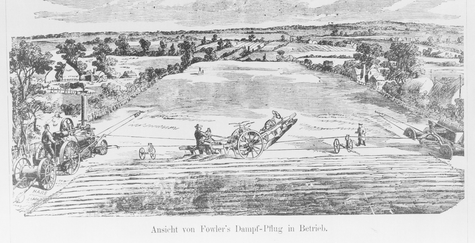

In March 1865, he married Julia Faul, the daughter of a Mannheim wine merchant. He found an ideal partner in the clever and educated young woman. For his young family Heinrich Lanz has a representative house built in A 2, 6, the later Hedwigsklinik. In 1867, Lanz begins to manufacture his own agricultural machinery. Above all, the fodder cutting machine becomes a great success. And threshing machines are also produced in Mannheim. Large machines, however, such as the first steam plow for the sugar factory in Waghäusel, still have to be imported from England.

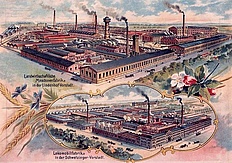

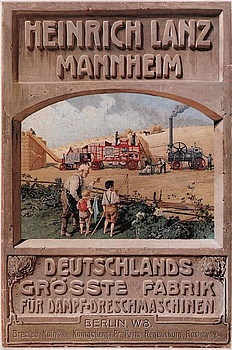

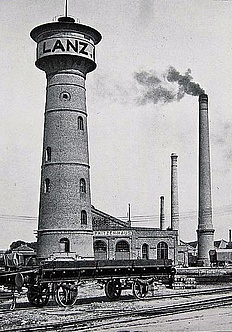

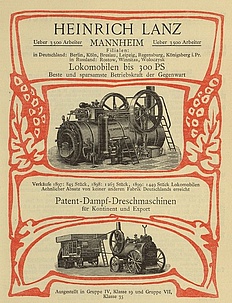

From January 1, 1870, Heinrich Lanz runs the company under his own name and expands the product range. For this purpose, a foundry is set up in 1873, which will be in operation until 1998. From 1879 onwards, the Heinrich Lanz company also produces steam threshing machines and locomobiles. These are transportable steam engines for driving implements. However, further expansion is no longer possible in the Schwetzinger Vorstadt. Therefore, in 1888, Heinrich Lanz buys land on the Lindenhof between Windeckstrasse and Meeräckerstrasse, provides it with a railroad siding and then gradually moves production to the new factory facilities. The only unchanged structure from this time is the water tower built in 1899.

At the 1900 World's Fair in Paris, the Heinrich Lanz company is able to present the world's largest locomobiles. Heinrich Lanz has made his company the most important producer of agricultural machinery on the European continent. His workers are not only among the best paid in Mannheim, but they also benefit from an unemployment fund, a company savings bank, and health and family benefits, which Lanz expands to form the Heinrich and Julia Lanz Foundation on his 60th birthday. He does not live to see the opening of the Heinrich Lanz Hospital he endowed in November 1907: he dies on February 1, 1905 at the age of 67 and is later buried in the family vault in Mannheim's main cemetery. A monument inaugurated in 1910 on the factory premises still commemorates Heinrich Lanz today.

His only son Karl, born after daughters Helene (1866), Emily (1867) and Valentine (1870)) in May 1873, took over the management of the company. After studying mechanical engineering, he joined the company in 1897. He wanted to promote innovation and organized races for motorboats such as the "Rhine Weeks" and the "Lake Constance Weeks". He is also involved in the field of aviation and in April 1909, together with engineer Johann Schütte, founds the company "Luftschiffbau Lanz & Schütte GmbH", which builds airships mainly for military use until 1918. Privately, Karl Lanz buys a neo-baroque palace in Mannheim's Oststadt for the then unbelievable sum of 5 million Reichsmarks (the equivalent of 28 million euros), the largest private house in Mannheim, into which the telegraph office moves in the mid-1950s .

When Karl Lanz hired the engineer Fritz Huber as a designer for the Heinrich Lanz company in September 1916, he probably had no idea what a stroke of luck he had made. Fritz was born in Wasserburg am Inn on March 8, 1881, the son of the merchant and master weaver Ludwig Huber and his wife Babette. He attended the secondary school in Wasserburg, then the industrial school in Munich and studied mechanical engineering at the Technical University in Munich from 1899. He graduated in 1903. The young engineer worked for various engine construction companies not only in Germany, but also in Switzerland, Austria and France. In the process, he deals with the construction of vehicle and ship engines as well as stationary engines and also designs "glow-head engines". In the process, he recognizes, that these could also be suitable for agricultural machinery. At the end of 1914, he volunteered for military service, became a medical officer and left the army in 1916 after a serious illness.

When he is hired by the Lanz company after his release from the military hospital on September 20, 1916, he initially builds gasoline-powered tractors for the German army. In 1918, he began to design a new type of glow-head engine at , which was to be used as a stationary engine to power small threshing machines and also other agricultural machinery. The four-stroke glow-head engine, which had already been invented in 1890 by the Englishman Herbert Akroyd Stuart, was regarded as a robust drive for ships.

In gasoline engines, which Lanz has been building into its tractors since 1911, combustion of the fuel-air mixture is initiated by ignition sparks; in diesel engines, the fuel itself ignites as a result of the high temperatures generated during heavy compression.

In the glow-head engine, the fuel is sprayed during compression onto the glowing hot inner wall of the combustion chamber, which is designed as a "glow head," where it vaporizes and ignites towards the end of compression.

In parallel with the development of the glow-head engine, Fritz Huber worked on his dissertation on "Vibration of Heavy Vehicle Engines," which he submitted to the TH München in 1919. In 1920, he was awarded a doctorate in engineering.

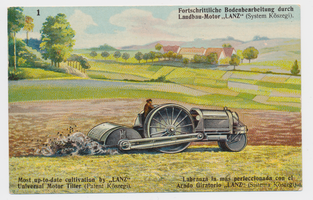

Due to the effects of the First World War, Huber was not able to test his glow-head engine until 1920, when he installed it in a tractor and developed it further. The economic situation after the First World War in Germany is difficult, also for the Lanz company. There is galloping inflation. Food is scarce, and people are starving and freezing. Many emigrate to America during this time. Although Lanz has been offering its "agricultural engine" since 1912. With a weight of 5 tons and drive wheels two meters in diameter , however, it is too big, too heavy and also much too expensive for small farms. But the shortage of labor, especially after the war, requires motorization of agriculture.

The tractors needed by the small farms must be small and robust, easy to operate, and easy to maintain and repair. Huber is convinced that only tractors with single-cylinder glow-head engines are suitable for this . He coins the motto: "The farmer's engine can't be single-cylinder enough."

Single-cylinder engines have a more compact and simpler design and also a lower engine weight than multi-cylinder engines. And glow-head engines have the advantage of being frugal and can run not only on diesel fuels or gasoline, but also on cheap substances such as kerosene, tran, vegetable oils, petroleum, spirit, and even crude oil. This fuel indifference, as Huber calls it, means an incredible advantage especially in the years after World War 1 when diesel or gasoline were hardly available.

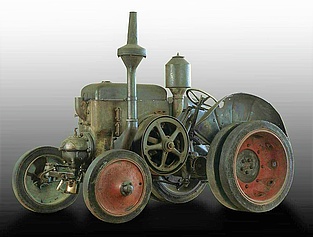

Initially, the Ortsbulldog, like the horse-drawn teaming bulldog with a drawbar, serves as an inexpensive substitute for locomobiles to power threshing machines or saws, for example. But as early as January 1921, Huber was able to demonstrate the world's first crude oil tractor to the astonished press in the Lanz factory yard. However, before the cold glow-head engine can be started, the ignition nose on the glow head must be preheated to about 700-800 ° C with a blowtorch. Then the fuel is injected by hand and, with the steering wheel removed for this purpose, the flywheel is started against the direction of rotation.

Huber does not use a reverse gear. To reverse, the direction of rotation of the engine is changed. During this reversal, the engine speed must be reduced until shortly before the engine comes to a standstill and then, with a lot of practice and skill, the throttle must be opened at the decisive moment. The resulting early ignition throws the engine back in the compression stroke, and it continues to run in the opposite direction. Simple wooden blocks, which are pressed onto the rear wheels via spindles, serve as brakes.

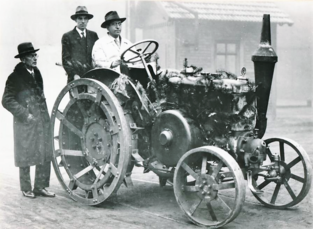

At the exhibition of the Agricultural Society in Leipzig in June 1921, the Lanz company proudly presented as a world novelty the crude oil tractor, the 12 hp Bulldog HL. Because of its squat appearance, the shape of its cylinder head with the vent holes that look like eyes, and not least because of its robustness, it is affectionately called the "Bulldog".

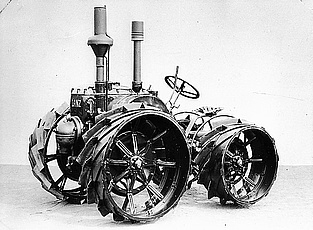

In 1923, the Ackerbulldog HP "Peter" with 15 hp and four-wheel drive is launched. With its large iron front and small rear wheels and its narrow width, it can even be used in the vineyard. In 1923, the "Felddank" was built especially for the field. As an inexpensive alternative, the little brother of the 12 hp bulldog, the "Mops" with only 8 hp, is offered in the same year, but only 250 of these are built until 1925. As a result of the depressed economy after the war, many farmers could not afford even this small Bulldog.

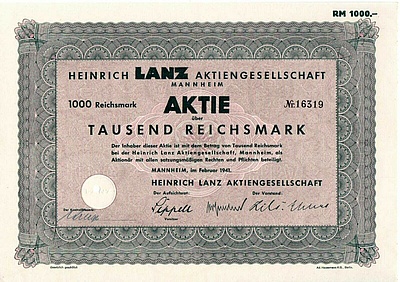

Many customers are granted deferred payment until after the harvest. But the resulting high level of outstanding accounts, as well as inflation, eventually lead to a liquidity bottleneck for Lanz. On condition that the company is converted into a joint stock company, the German bank grants the company a loan.

In order to demonstrate the performance of the indestructible Bulldog, the Lanz company launches starts an endurance test drive to Berlin on November 10, 1924. After a total of almost 400 hours, the Bulldogs, which started at the Heinrich Lanz monument, reach the Victory Column on November 27 without a breakdown or accident....

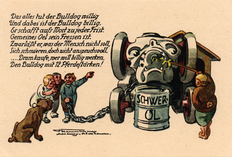

Under Huber's leadership, numerous other universally usable Bulldog engines are constructed for various applications. What they all have in common is not only their economy, but also their versatility as farm tractors, as tractors and - equipped with a clutchable pulley - also as stationary drives for numerous auxiliary devices such as grinders, balers, threshing machines, forage harvesters, water pumps, circular saws etc. Postcards with funny rhymes advertise the Bulldog. They rhyme: "The Bulldog does all this willingly, and the Bulldog is cheap. He creates on the word to every term, Common oil is his food. Although he can be lubricated, which man should not, but not fastidiously".

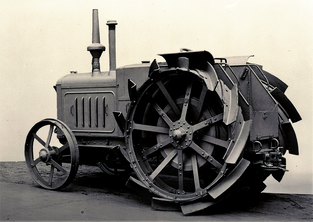

With the HR 2 large bulldog, Huber developed a bulldog with a continuous output of 28 hp for large farms in 1926. The HR is again available both in a field version with iron wheels and as a traffic bulldog with twin tires , and it even has a device for spreading sand in front of the rear wheels. It is the first Bulldog to be manufactured on an assembly line, following Ford's example. This allows 18 Bulldogs to be produced daily at low cost. Incidentally, the 175-meter-long assembly line is the first in Germany. In 1928, the HR 4, the first Bulldog equipped with thermosyphon cooling, follows. This water-saving cooling method uses natural convection: hot water rises to the top and cool water falls to the bottom. There is no need for a pump. The HR 5 of 1929 was the first to feature a transmission with a reverse gear. So did the HN 1 type, called the "radiator bulldog", which was produced from 1932.

From 1929, the Bulldogs are fitted with pneumatic tires from Continental and can now be driven both on the field and on the road without the time-consuming task of replacing the iron wheels with rubber tires for road transport after use on the field. In addition, pneumatic tires now made it possible to triple the speed of the tractors, which had previously only been able to travel at 6 km/h.

When Süddeutsche Bank took over the majority of shares in 1931, the company became part of the Röchling Group and the Lanz family left the company. Helene, Heinrich Lanz's eldest daughter, had married August Röchling in March 1885.

When Süddeutsche Bank took over the majority of shares in 1931, the company became part of the Röchling Group and the Lanz family left the company. Helene, Heinrich Lanz's eldest daughter, had married August Röchling in March 1885.

But Huber remained loyal to the company and became its director in 1935. In 1939, he succeeded in developing the 15 hp light tractor with electric starter called the "Bauern Bulldog".

When Dr. Fritz Huber dies of a gall disease in Mannheim on April 14, 1942, Lanz is the largest German agricultural machinery manufacturer. In the year of his death, the 100,000th Bulldog is delivered in Mannheim. Production of the Bulldogs continues after Huber's death, albeit only with wood carburetor drive as a result of the wartime fuel shortage. Dr. Huber is spared the experience of seeing how the air raids turn the factory into a field of rubble during World War II.

Reconstruction work began in the summer of 1945. But this proved to be very difficult due to the extensive damage and the scarcity of building materials. And so it was not until 1950 that a new 16 hp Bulldog could be presented as the successor to the 15 hp Bauern Bulldog. But Lanz was no longer able to build on its old successes. The sales territories in the East are lost, domestic sales shrink, and a high back tax demand completely consumes the liquidity.

Nevertheless, the shareholders expect their dividend, which is initially paid from the company's assets and two years later from the proceeds of the sale of the land on which the airship "Schütte-Lanz" was once built.

In order to maintain continuous employment, production continues despite all adversities. But then the tractors that had not been sold over a period of two months piled up in the warehouses and even in the factory yard. The value of Lanz shares falls, and finally in 1956, after protracted negotiations, Süddeutsche Bank, the largest shareholder, sells its block of shares to "Deere & Company Moline" in Illinois, which had already expressed an interest in Lanz four years earlier. Through further acquisitions, John Deere soon held the majority of shares.

Heinrich Lanz had visited the John Deere agricultural machinery factory in Illinois in 1902 and met Charles Deere, the son of the company founder John Deere, who died in 1886. Born in Vermont in 1804, John Deere was a typical American self-made man. Raised alone by his mother after his father's untimely death, he became very successful as a young blacksmith because of his craftsmanship and inventiveness. After developing a self-cleaning steel plow in 1837, he went into business for himself in Illinois and founded the company that still bears his name today.

With the takeover by John Deere in 1956, the glorious era of the traditional Lanz company came to an end. At first, there were great reservations about the American company. Thus, the "Deutsche Bauernzeitung" writes "we are by no means able to see an ideal situation in the fact that a company of the importance and tradition of the House of Lanz, which was once considered the largest agricultural machinery and tractor factory in Europe, will in the future receive its instructions from the USA." Indeed, the changeover is taking a toll on the workforce. But the new "John-Deere-Lanz AG," as the company has been called since 1960, offers prospects for the future. Without the takeover, Lanz would have had to file for bankruptcy, and there would probably no longer be an agricultural machinery factory in Mannheim today.

The Americans invested large sums of money in the factory and expanded it into the European headquarters from where, in addition to Lanz products, they primarily marketed their own agricultural machinery.

When production of the Bulldogs was finally discontinued in 1960, a total of almost 220,000 Bulldogs had left the factory. And the traditional blue and red color of Lanz products also disappears. The company color of John Deere is green for the vehicle and yellow for the rims and inscription. In 1967, the company name is changed to "John Deere Werke Mannheim, Branch of Deere & Company".

Today, everyone is happy to have John Deere, the world's largest agricultural machinery manufacturer, in Mannheim. The Mannheim tractor plant is John Deere's largest factory outside the USA. Tractors are exported from here to over 100 countries. And of course, with many innovations, the tractor has since been further developed into a high-tech machine that enables precision farming via GPS control. This year, John Deere is even introducing a fully autonomous tractor. This can be programmed via smartphone, tablet or computer and can also be monitored remotely.

But the legendary, ingeniously simple design and indestructible Bulldog has become synonymous with tractors. Its versatility paved the way for the mechanization of agriculture. Heinrich Lanz still looks out over the factory grounds from his monument today, and he probably likes what he sees.